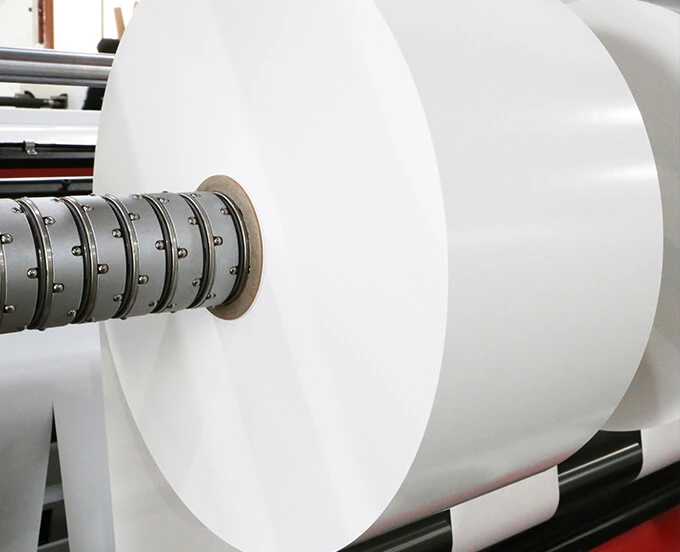

TOP A/B slitter is the most hot selling type in Raloyal.

As it has the most competitive price and wide application: can slit material not only label stock, but also flexible film, laminated material, aluminium foi, non-woven fabric, etc. related industry included: Food, Wine, Beverage, Logistics, New Energy, Electrics, Optics, Medicine, etc.

Machine owns 3 servo motors, shaftless loading, differential shaft, twin fork.

This TOP A/B slitter unwind roll diameter can reach max Φ1200mm.

Rewind roll diameter Φ600mm as standard, can be customized as Φ800mm to meet different request of market.

Also can choose the function of: auto push, automatic blade set (for both razor blade and circular knife).

The excellent features and the most competitve price, decided it is the favorite for market.

This slitter we have sold more than 200 sets, exported to more than 20 countries. It is very ideal machine type for the label supplier and print house, global label product company such as: ARCLAD , AVERY, FleksoGraf, etc. adopted this type.

There are three categories of high speed tape slitting machine for sale: standard high speed slitting machine, standard high speed slitting machine with slip shaft, and standard high speed slitting machine with slip shaft and shaftless unwinding chuck. Standard high speed slitting machine plus PLC can reach the high speed of 200m/min. There are also three sizes of high speed roll slitting machine for sale can be chosen to meet all kinds of width of raw materials. They are 1300mm, 1700mm, 2000mm. Standard high speed slitting machines are ideal for mass production of tape, packaging, printing, paper, etc.

If you want to uplift the precision of material slitting and rewinding, the standard high speed slitting machine with slip shaft is very suitable and highly recommended. Slip shaft can achieve the perfect fixing for different kinds of materials rewinding, and can reduce the cost waste occurred at the same time. This high speed paper roll converting equipment is controlled by two servo motors, which control the unwinding and 2 slip shafts rewinding, making the tension be controlled much better and rewinding more smoothly and slitting more accurately.

Standard high speed slitting machine with slip shaft and shaftless unwinding chuck is ideal for large-diameter heavy rolls and can solve the problem of tube deformation. And the speed of this high speed roll converting equipment is 300m/min. It is an ideal slitting machine for demanding production at high speed and high precision.

Slitting is a converting process cutting wide mother material rolls to narrow ones. In rewind slitting process, the material roll will be fed into the unwind section, slit in the slitting section and rewind on one or more shafts to form narrower rolls. For the high speed roll converting equipment that can rewind slit, we call it a slitting machine, a slitter or a slitter rewinder

High speed slitting and rewinding machine can be divided into three sections: unwind section, slitting section and rewinding section. High speed slitting machine is widely used

for slitting soft materials such as adhesive labels, plastic films, paper and non-woven and also hard material like metal, copper foil and aluminum foil. The slitting part has some options suh as razor slitting, rotary shear slitting, crush cut slitting and hot knife slitting. Razor slitting is very simple to set and low price, but it needs to be changed frequently.

This is widely used on thin plastic films. As to Rotary shear slitting, as its names suggest, the slitting provides a scissor cutting effect. It works well with slitting foils, paper and plastic films. As to crush cut slitting, it an ideal for slitting non-wovens and foams. Hot knife slitting applies to a heated blade to cut through an anvil.

Automatic Loading:

Automatic loading by cylinder

Splicing Table:

Friendly operating and increase productivity.

Automatic Length Counter:

count the length automatically

Slitting Knife:

Self-lock type knife, shorten set-up time and protect the knife shaft.Safety

cover for slitting section to ensure safty.

Friction Shaft:

Separated tension automatic adjustment. Double beads type friction shaft,

with high precision.